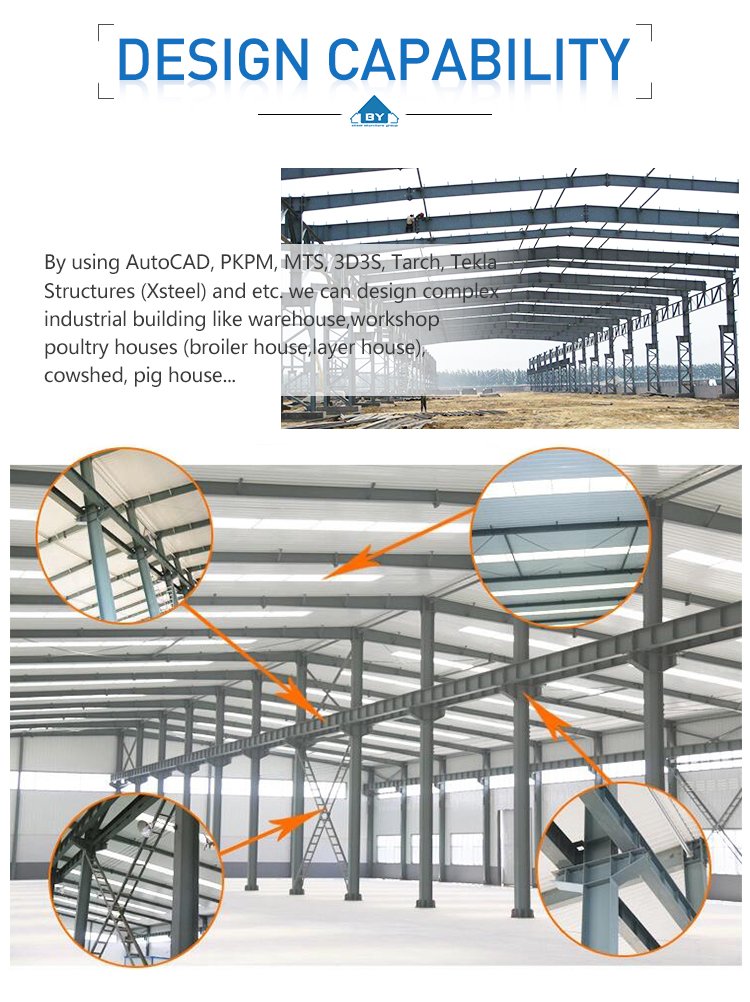

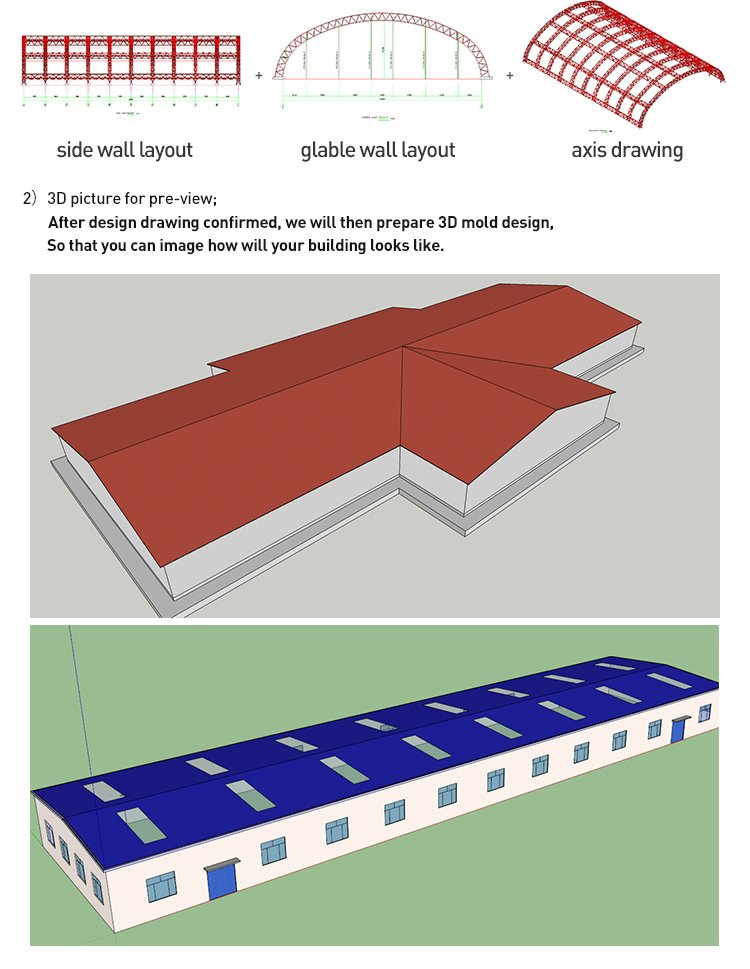

Design future:

Shentong International has established overseas warehouses, such as in Hong Kong, the United States, the European Union, and Australia." All the warehouses are mostly built by steel structures with the wall & roof of sandwich panels.

Shentong International's overseas warehouses, situated strategically in Hong Kong, the United States, the European Union, and Australia, not only serve as hubs for efficient logistics operations but also reflect the company's commitment to sustainability and innovation. The warehouses, predominantly constructed with steel structures, exude a modern and industrial aesthetic, blending strength and durability with functionality.

The steel frameworks of these warehouses provide exceptional resistance to weather elements, ensuring the safety and integrity of the stored goods. The sandwich panels used for the walls and roofs offer excellent insulation, maintaining a comfortable temperature within the warehouses, reducing the need for energy-intensive heating and cooling systems.

Moreover, the use of steel and sandwich panels in the construction of these warehouses is environmentally friendly. Steel is a recyclable material, minimizing waste and environmental impact. Additionally, the insulation provided by the sandwich panels helps in reducing energy consumption, further contributing to Shentong International's sustainability goals.

In the future, Shentong International plans to expand its network of overseas warehouses, leveraging advanced technologies and sustainable building materials to enhance operational efficiency and reduce environmental impact. These warehouses will continue to serve as the backbone of the company's global logistics operations, enabling it to deliver exceptional service to its customers worldwide.

Steel structure Specification:

1. Material: Q235B or Q355B

2. Project size: Length ranges from 20 to 300m, width from 10m to 60m, and eave height from 2.5m to 30m.

3. Span: single or multi span

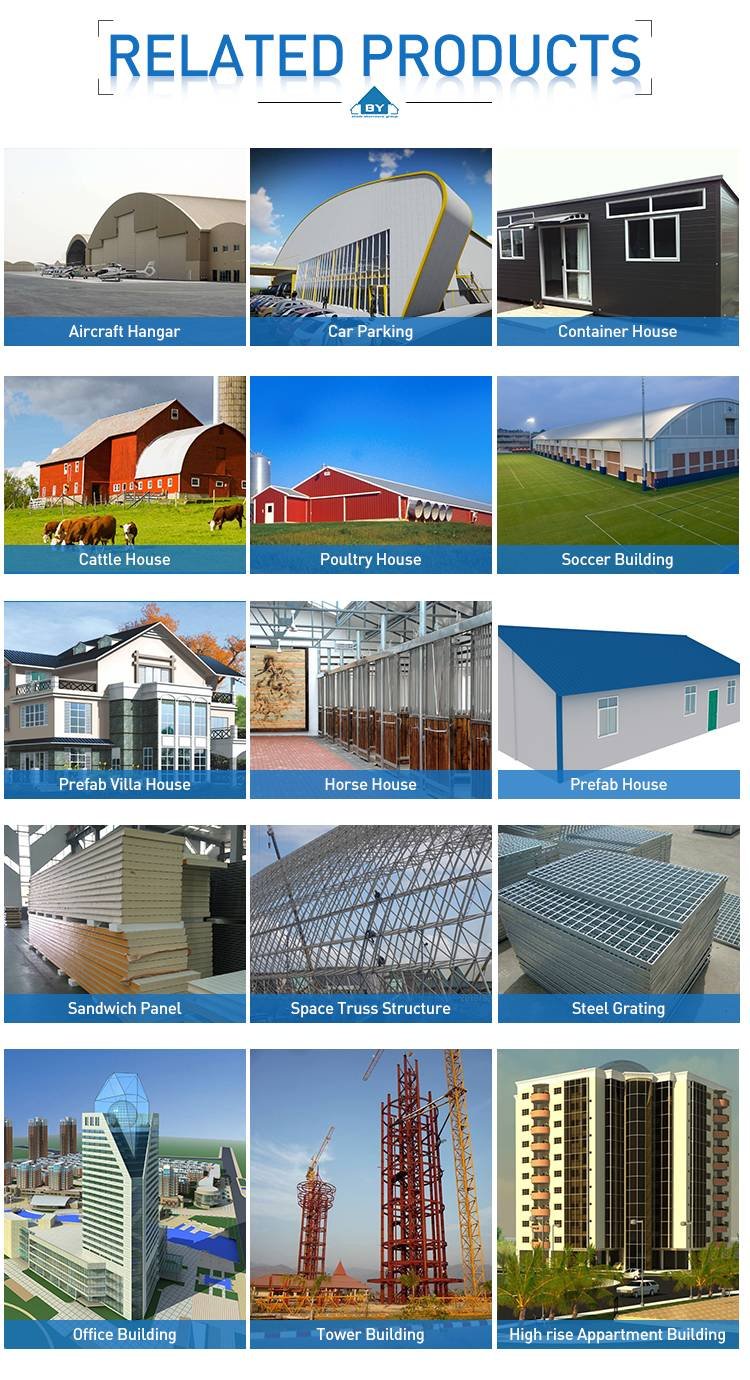

4. Building Type: warehouse, workshop, Agricultural projects, high rise, heavy industrial steel structure, car parking, Large scale span projects...

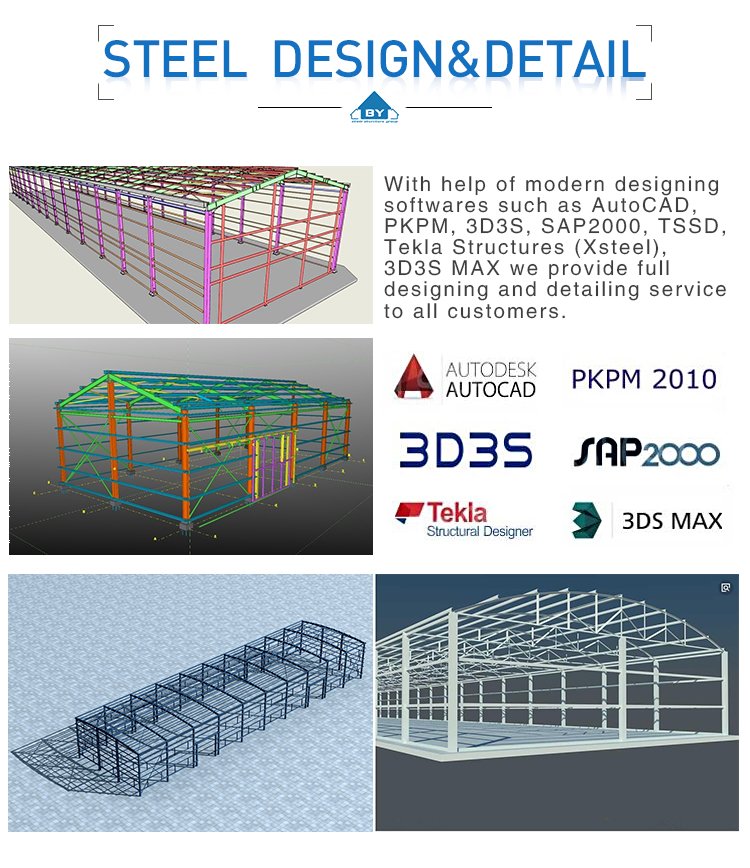

5. Design: Fabricate based on clients design or our design based on Customer’s Technical data.

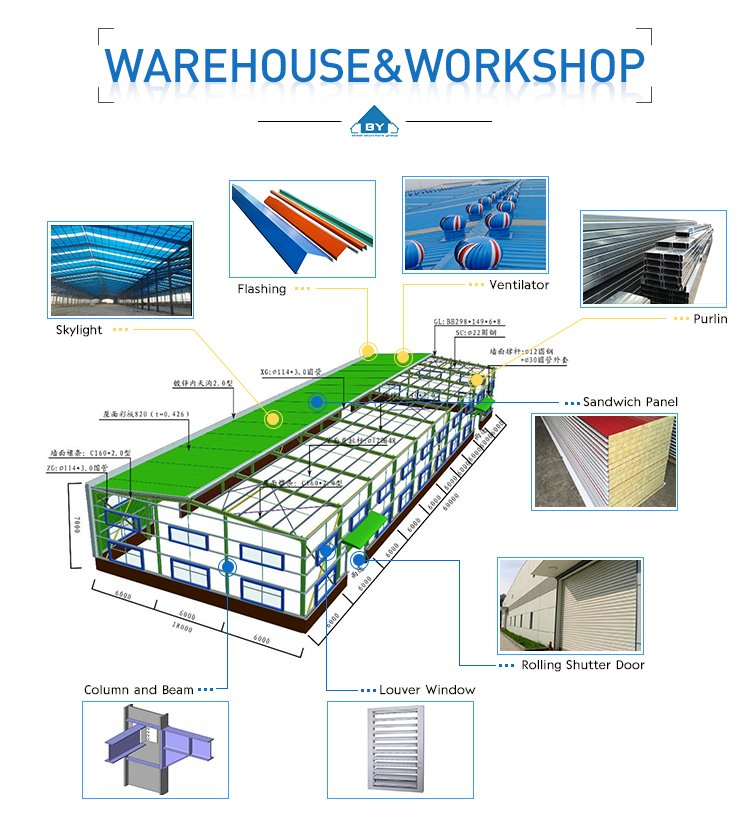

The structure materials:

1. Main structure: built up or hot rolled H beam.

2. Purlin: galvanized C purlin and Z purlin

3. Wall and Roof Materials: EPS / Rock wool /Fiber glass/PU sandwich panel or corrugated steel sheet/ Aluminium plate/ Curtain wall

4. Tie rod: circular steel tube

5. Wall &roof sag rod: round bar or angel steel finish with hot dipped galvanizing or anti rust primer paint

7. Column & roof bracing : Steel Bar/ angle steel / square tube.

8. Fly bracing: angle steel L50x5

10.. Roof gutter: steel sheet, Galvanized steel sheet, Aluminum sheet and stainless steel sheet.

11. Rain spout: PVC pipe / Aluminium pipe/steel pipe

12. Doors: sliding sandwich panel doors, rolling shutter door, high speed shutter door or metal doors, Aircraft Gate.

13. Windows: PVC window, aluminum window

14. Surface finishing: hot dipped galvanizing or anti rust primer coating.

15.Design: Tailored to client's needs or professionally designed by our team

16.Quality Assurance: Ensured by manufacturers with stringent quality control measures or through the utilization of third-party inspection services

17.Installation: Assisted by our engineers during the installation process or on-site supervision provided by our dedicated engineering team

18.Warranty: Guaranteeing a structural lifespan exceeding 50 years for the primary structure

The information required for the quotation is as follows.

1. Building area: Length x width x eave height (mm ) or Please send us your detailed drawings?

2. Wind speed (Km/h)and snow load (kg/m2) at construction site?

3. Roof and wall material: What type of wall and roof materials do you need?

4. Windows and doors: How many doors and windows do you need? What is size and materials?

5. Do you need the ventilator for the warehouse?

6. Steel structure finishing: do you want primer coating (paint, what kind of paint or just normal brand?) or hot dip galvanized?